LT3645 查看數據表(PDF) - Linear Technology

零件编号

产品描述 (功能)

比赛名单

LT3645 Datasheet PDF : 24 Pages

| |||

LT3645

APPLICATIONS INFORMATION

Output Capacitor

The output capacitor has two essential functions. Along

with the inductor, it filters the square wave generated

by the LT3645 to produce the DC output. In this role it

determines the output ripple so low impedance at the

switching frequency is important. The second function

is to store energy in order to satisfy transient loads and

stabilize the LT3645’s control loop.

Ceramic capacitors have very low equivalent series re-

sistance (ESR) and provide the best ripple performance.

A good value is:

COUT = 26.4/(VOUT • ƒ)

where f is the switching frequency in MHz and COUT is in

μF. This choice will provide low output ripple and good

transient response. COUT = 10μF is a good choice for

output voltages above 2.5V. For lower output voltages

use 22μF or higher.

Transient performance can be improved with a high value

capacitor, but a phase lead capacitor across the feedback

resistor R1 may be required to get the full benefit (see the

Compensation section). Using a small output capacitor

results in an increased loop crossover frequency.

Use X5R or X7R types and keep in mind that a ceramic

capacitor biased with VOUT will have less than its nominal

capacitance. High performance electrolytic capacitors can

be used for the output capacitor. Low ESR is important, so

choose one that is intended for use in switching regulators.

The ESR should be specified by the supplier and should be

0.1Ω or less. Such a capacitor will be larger than a ceramic

capacitor and will have a larger capacitance, because the

capacitor must be large to achieve low ESR.

Table 2 lists several capacitor vendors.

Table 2. Capacitor Vendors

AVX

Murata

Taiyo Yuden

Vishay Siliconix

TDK

www.avxcorp.com

www.murata.com

www.t-yuden.com

www.vishay.com

www.tdk.com

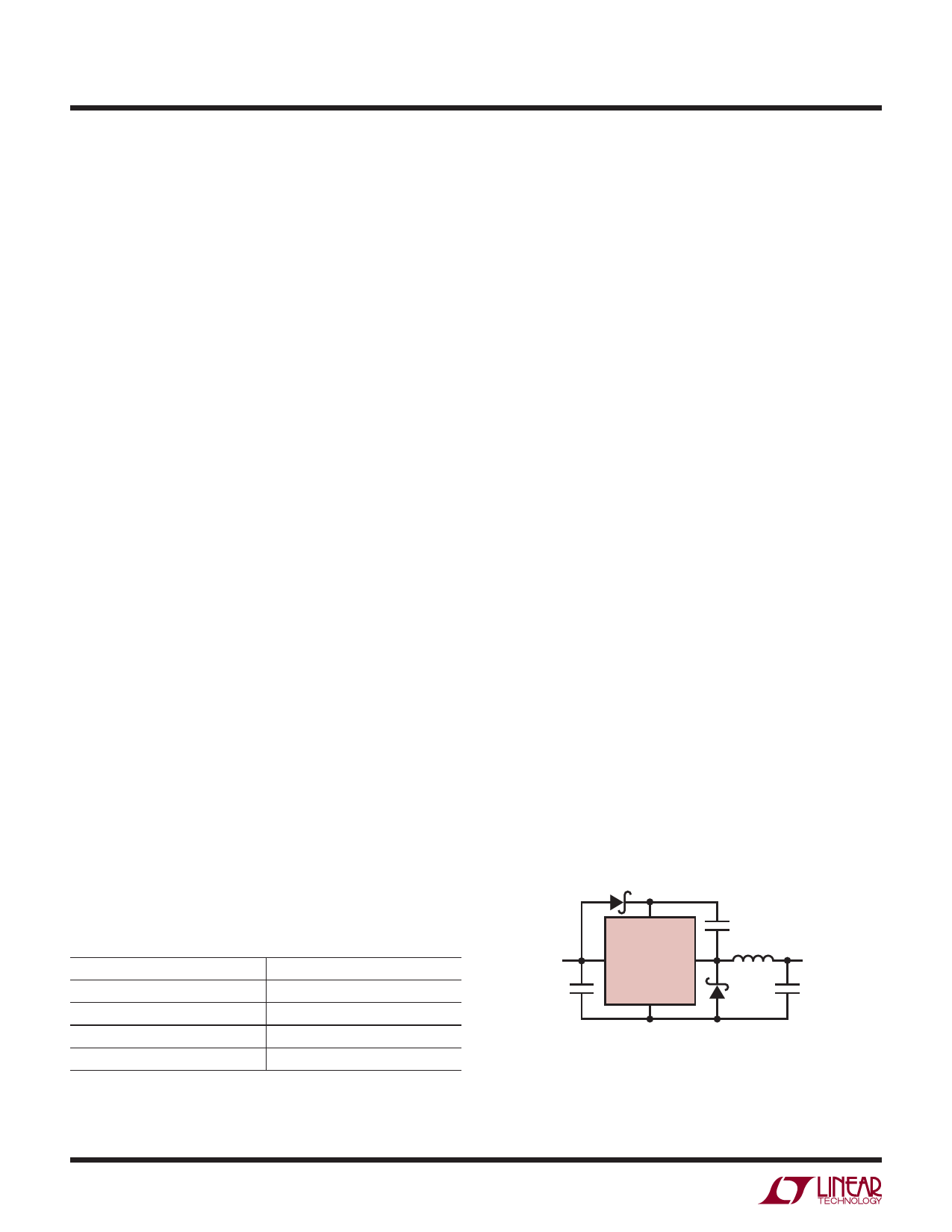

BOOST Pin Considerations

The external capacitor C2 and an internal Schottky diode

connected between the VCC2 and BOOST pins form a

charge pump circuit which is used to generate a boost

voltage that is higher than the input voltage (VIN). In most

application circuits where the duty cycle is less than 50%,

use C2 = 0.1μF. If the duty cycle is higher than 50% then

use C2 = 0.22μF.

The BOOST pin must be at least 2.2V above the SW pin

to fully saturate the NPN power switch (Q1). The forward

drop of the internal Schottky diode is 0.8V. This means

that VCC2 must be tied to a supply greater than 2.6V.

VCC2 may be tied to a supply between 2.2V and 2.6V if an

external Schottky diode (such as a BAS70) is connected

from VCC2 (anode) to BOOST (cathode).

If no voltage supply greater than 2.6V is available, then

an external boost Schottky diode can be tied from the

VIN pin (anode) to the BOOST pin (cathode) as shown in

Figure 3. In this configuration, the BOOST capacitor will be

charged to approximately the VIN voltage, and will change

if VIN changes. In this configuration the maximum operat-

ing VIN is 25V, because when VIN = 25V, then when the

power switch Q1 turns on, VSW ~ 25V, and since the boost

capacitor is charged to 25V, the BOOST pin will be at 50V.

This connection is not as efficient as the others because

the BOOST pin current comes from a higher voltage.

The minimum operating voltage of an LT3645 application

is limited by the undervoltage lockout (~3.4V) and by

the maximum duty cycle as outlined above. For proper

startup, the minimum input voltage is also limited by the

D2

BOOST

C3

LT3645

VIN

VIN

SW

GND

VBOOST – VSW % VIN

MAX VBOOST % 2VIN

Figure 3.

VOUT

3645 F03

3645f

12