MCCF33095 查看數據表(PDF) - Motorola => Freescale

零件编号

产品描述 (功能)

比赛名单

MCCF33095 Datasheet PDF : 12 Pages

| |||

MCCF33095 MC33095

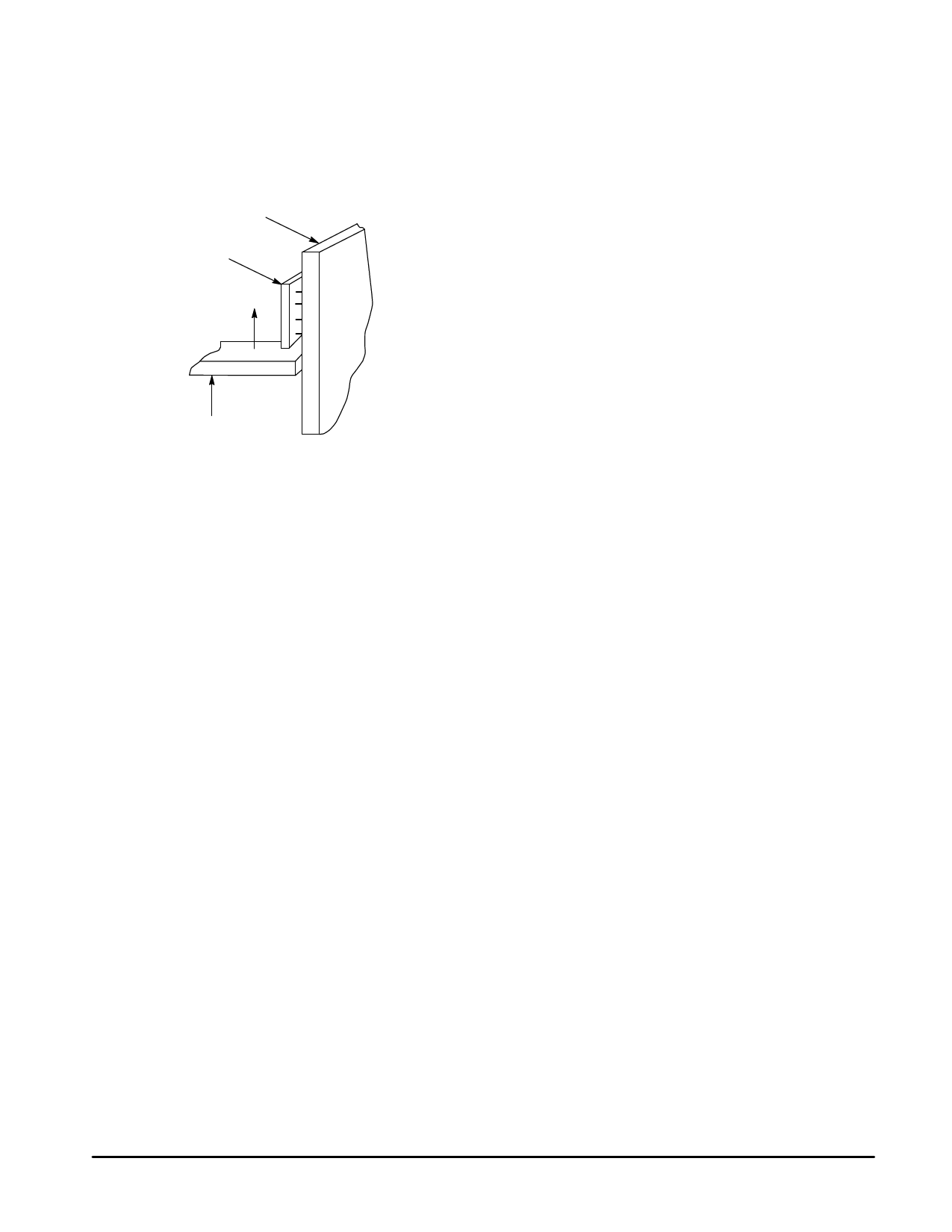

Shear strength testing should meet a 0.8 Newtons/Bump

criteria. Shear strength testing should follow thermocycling of

the chip from – 40° to +140°C to insure the stability of shear

strength over temperature. Figure 13 depicts a test set–up

which might possibly be used.

Figure 13. Shear Test Fixture

Substrate

Flip–Chip

Cantilever Arm

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

Aside from physical contamination, flip–chips, like any

other chips, should not be handled directly due to the fact that

electrostatic discharges can cause permanent damage to the

electronic circuit. Flip–chips which do survive an electrostatic

discharge can be left in a weakened condition resulting in

reduced reliability of the end product. To avoid electrostatic

damage of the circuit, assembly personnel should make use

of a wrist strap or some other device to provide electrostatic

grounding of their body. For the same reason, machinery

used to assemble semiconductor circuits should be

electrostaticly grounded.

Flip–chips rely primarily on the thermal path established by

the bumps to remove heat from the chip as a result of internal

circuit operation. Standard Motorola flip–chips have a thermal

resistance of approximately 290°C/W/Bump. This figure can

be used to estimate the allowed maximum power dissipation

of the chip.

Cost and Equipment Manufacturers

The cost of implementing a flip–chip assembly process

depends on the specific production requirements and as a

result will vary over a broad range. It is possible to implement

a small volume laboratory set–up for a few hundred dollars

using manual operations. At the other end of the scale one

could spend millions setting up a fully automated line

incorporating pattern recognization, chip and substrate

orientation, reflow, cleaning, and test. The module fabricator

will have to make this assessment.

An assembly operator can manually accomplish the pick

and place operation using a vacuum probe to pick–up and

orient the flip–chip onto the substrate. Furthermore, it is

possible to perform the reflow assembly operation using a

simple batch process oven fabricated from a laboratory hot

plate. However, the use of such process techniques will have

questionable impact on the final product’s reliability and

quality. For this reason, it is highly recommended that the

module fabricator seriously consider two major pieces of

equipment; a pick and place machine and an infrared solder

reflow oven. Both pieces of equipment can vary over a wide

cost range depending on the production requirements. A

partial list of manufacturers for this equipment is given below.

Pick and Place Machine:

Universal Instruments Corp.

Dover Technologies, Inc.

Binghamton, NY 13902

(607) 772–7522

Seiko

Torrance, CA 90505

(310) 517–7850

Laurier Inc.

Hudson, NH 03051

(603) 889–8800

Infrared Reflow Oven:

BTU

Bellerica, MA 01862

(508) 667–4111

Vitronics

Newmarket, NH 03857

(603) 659–6550

Additional Applications

Completed ceramic flip–chip sub–assemblies can be

stacked one on top of another to produce an overall

assembly by making contact connections through bumps.

This technology is beginning to emerge in the computer

industry where physical module size is of significant

importance. Furthermore, this assembly technology, though

more complex, is undergoing serious consideration within the

automotive industry as well.

Applications requiring small size and high reliability at high

ambient temperatures can benefit considerably through the

implementation of flip–chip assembly techniques.

10

MOTOROLA ANALOG IC DEVICE DATA