MCCF33095D 查看數據表(PDF) - Motorola => Freescale

零件编号

产品描述 (功能)

比赛名单

MCCF33095D Datasheet PDF : 12 Pages

| |||

MCCF33095 MC33095

Reflow

The reflow process creates a thermally induced amalgam

of the lead and tin. In the melting process, the surface tension

is equalized causing the melted solder to uniformly ball up as

mentioned earlier.

The ideal reflow oven profile gradually ramps up in

temperature to an initial plateau. The purpose of the plateau

is to establish a near equilibrium temperature just below that

of the solder’s melting temperature. Following the preheat, a

short time and higher temperature excursion is necessary.

This is to ensure adequate melting of the solder materials.

The temperature is then ramped down to room temperature.

An atmosphere of hydrogen is used during the reflow heat

cycle. The hydrogen provides a reducing atmosphere for the

removal of any surface oxides present. The formation or

presence of oxides can cause degradation in the bond

reliability of the product.

During the flip–chip attachment reflow onto the ceramic

substrate host, the created surface tension of the molten

solder aids in the alignment of the chip onto the ceramic

substrate.

Reliability

Motorola is determined to bring high quality and reliable

products to its customers. This is being brought about by

increased automation, in–line Statistical Process Control

(SPC), bump shear strength testing, thermocycling from

– 40° to +140°C, process improvements such as backside

laser marking of the silicon chip, and improved copper

plating techniques.

substrate from external moisture. A commonly used gel for

this purpose is Dow Corning 562. As a final module assembly

step, a cover is recommended to be placed over the ceramic

assembly for further protection of the circuit.

It should be pointed out that the commonly used ceramic

substrate material, though more expensive than other

substrate materials, offers significantly superior thermal

properties. By comparison, the use of ceramic material offers

33 times the thermal advantage of the second best material,

Ceracom. The common FR–4 epoxy material is 100 times

less thermally conductive than ceramic. For applications

where dielectric constants are important and/or heat

dissipation is not of real importance, other less costly

materials can be used. The basic concept of the process is

identical for all flip–chip substrates used.

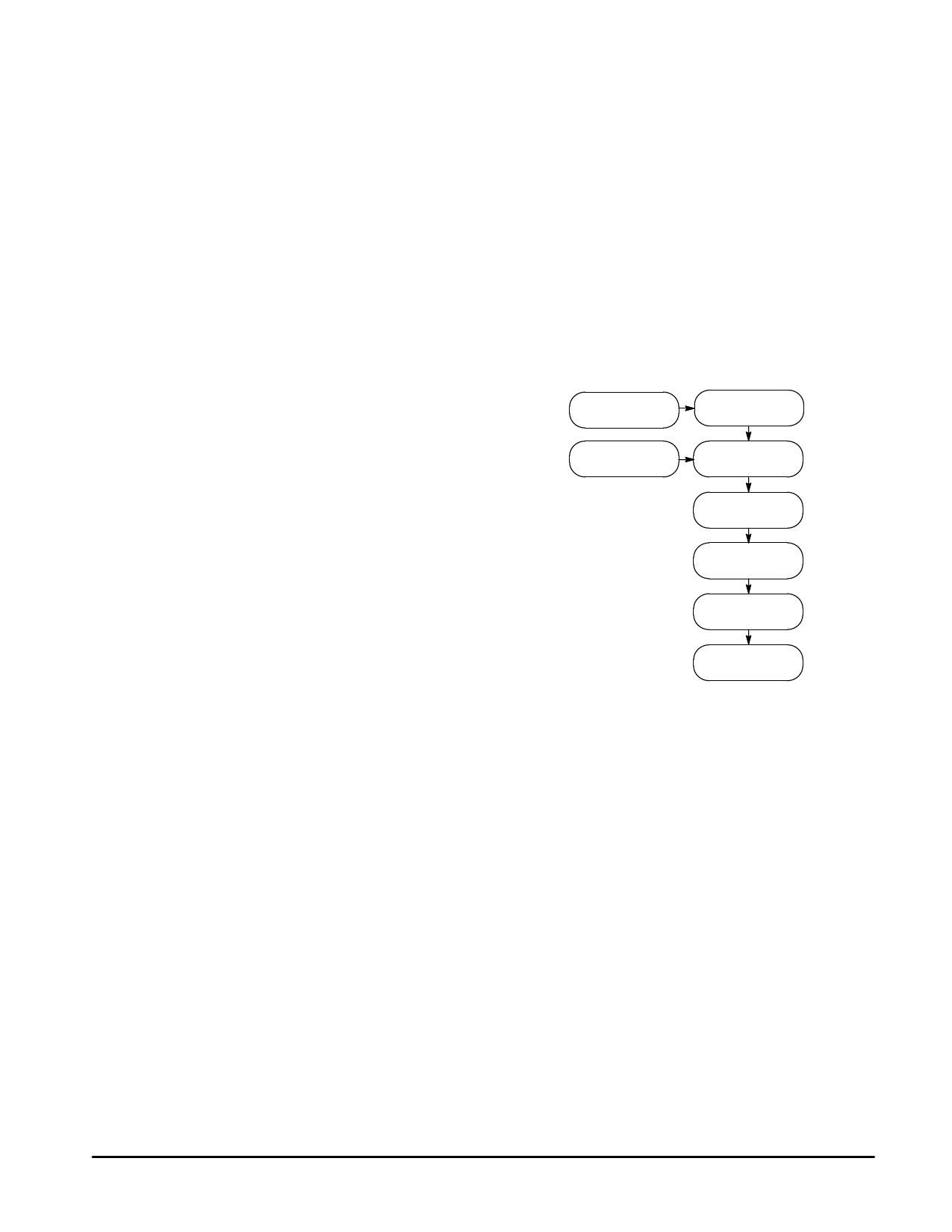

Figure 10. Process Flow Diagram

Printed Circuit

Board (PCB)

Bumping PCB

Bumped Chip

Bumped PCB

on Pallet

Chip Placement

IR Reflow

ATTACHING FLIP–CHIPS ONTO

CERAMIC SUBSTRATES

Overview

The assembly or process of attaching the flip–chip onto a

ceramic substrate is performed by the module fabricator.

Prior to actual assembly, the ceramic substrate should

undergo several process steps. Care should be exercised to

properly orient the flip–chip onto the substrate host in order to

accommodate the appropriate solder bumps. Ideally, the

flip–chip should be removed from the waffle pack with a pick

and place machine utilizing a vacuum pick–up to move the

die onto the ceramic substrate. Any other components to be

reflow soldered onto the substrate can be placed onto the

substrate in a similar manner. Flip–chip assembly onto a

ceramic substrate allows for some passive components,

such as resistors, to be formed directly into the ceramic

substrate circuit pattern itself. With all surface components to

be mounted in place on the ceramic substrate, the assembly

is moved into the furnace where it undergoes a specified

temperature variation to solder all the components onto the

ceramic substrate. This is accomplished by melting

(reflowing) the substrate solder bumps. The resulting

assembly should, after being cooled, be cleaned to remove

any flux residues. If the substrate assembly is to be mounted

into a module, it is recommended that the cavity of the

module be filled with an appropriate silicon gel. The use of a

gel coating helps to seal the individual components on the

Cleaning

Encapsulation

Ceramic Substrate Preparation

The recommended ceramic substrate is aluminum oxide.

These substrates come connected in what is referred to as a

card. This is identical to the concept of die or chips on a wafer.

Each card usually contains 8 to 16 substrates.

Initially, the ceramic should be precleaned with isopropyl

alcohol, followed by freon. The bump pattern is then

transferred onto the substrate using a metal stencil technique

using a palladium silver conducting paste, such as DuPont

9476, through a #325 mesh. Once the pattern is applied, the

substrate is dried for ten minutes at 150°C and then fired for

60 minutes at a temperature increasing to a peak of 850°C for

ten additional minutes. Solder paste is then stenciled onto

the pads.

A metal etched stencil defining the contact areas is

recommended. The use of an etched stencil affords better

solder paste control than does a silk screen. The metal stencil

affords a deposition of a known amount of solder paste,

thereby preventing bridging caused by excess solder usage.

8

MOTOROLA ANALOG IC DEVICE DATA